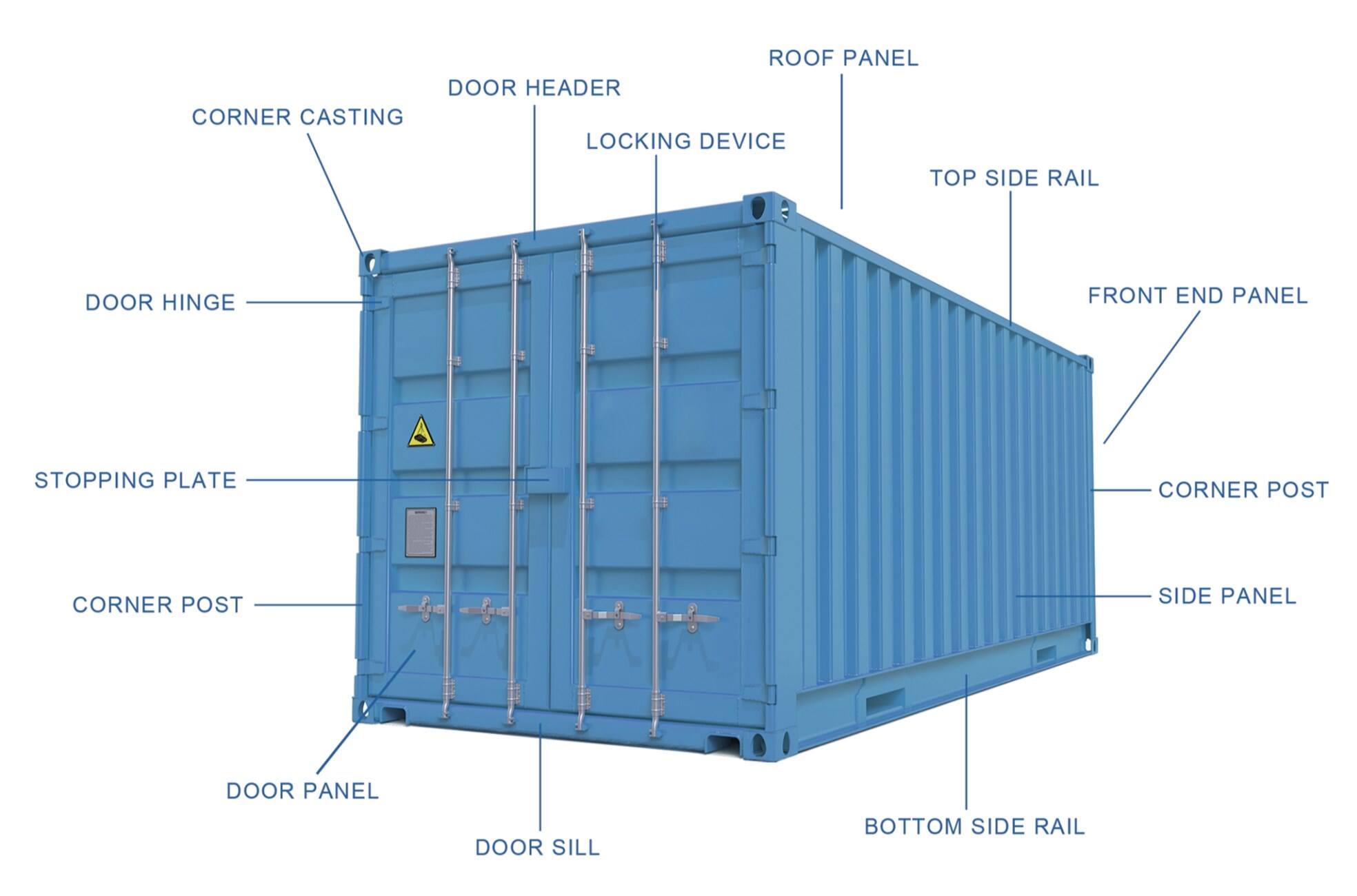

The vastness of the ocean conceals relentless challenges for global shipping—violent storms, corrosive saltwater, and towering waves. Amid these extremes, the humble container corner casting plays a pivotal role in safeguarding cargo, crews, and vessels. Often overlooked, these steel fittings are engineered to withstand forces that would cripple lesser structures. This article delves into how corner castings protect containers during maritime transport and why their design is critical to modern shipping.

1. The Ocean’s Threats to Containers

Maritime environments expose containers to:

Dynamic Loads: Rolling ships generate shifting forces exceeding 4G during storms.

Saltwater Corrosion: Spray and humidity accelerate metal degradation.

Stacking Pressures: A single 20,000 TEU vessel carries 200,000+ tons of vertically stacked containers.

Corner castings are the first line of defense against these threats.

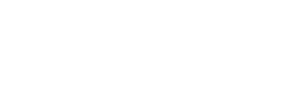

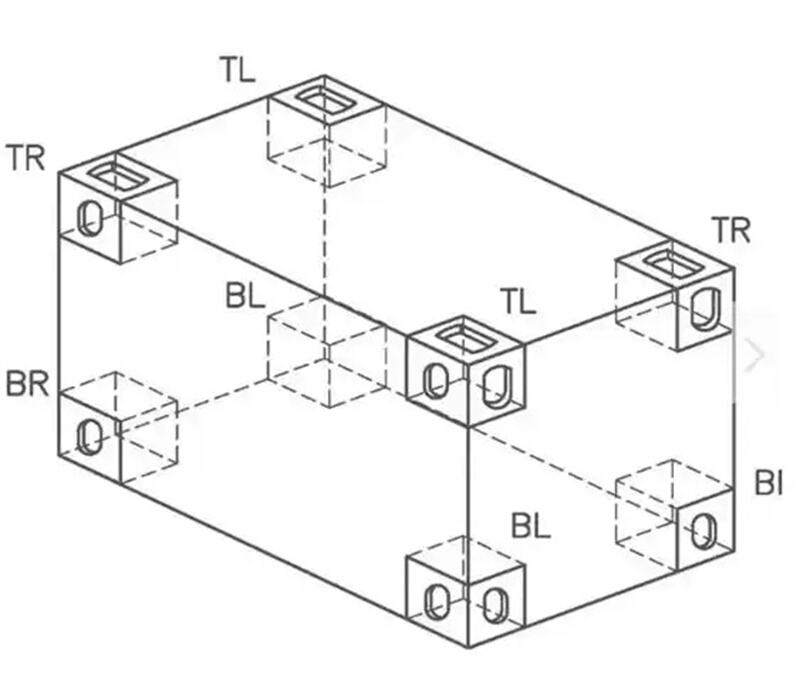

2. Corner Castings: Engineering for Survival

A. Structural Integrity Under Stress

ISO 1161 Compliance: Castings must endure vertical loads up to 200 tons and horizontal forces of 150 kN.

Shock Absorption: Their ductile cast steel design redistributes stress during violent motions, preventing container deformation.

Twist-Lock Integration: Interlocking with ship cell guides stabilizes containers, reducing sway by 40% in rough seas.

B. Corrosion Resistance

Zinc Spray Coating: Galvanization protects castings from saltwater, extending lifespan by 15–20 years.

Drainage Design: Angled apertures prevent water pooling, a common cause of rust in older models.

Epoxy-Painted Variants: Used for chemical or high-humidity cargoes, these resist acidic salt deposits.

C. Stacking Safety

Load Distribution: Castings channel 80% of vertical stack weight to the container frame, minimizing panel stress.

Interlock Fail-Safes: Even if one twist-lock disengages, adjacent castings maintain stack stability.

Anti-Collision Bevels: Rounded edges prevent damage during crane misalignments in busy ports.

3. Case Studies: Corner Castings in Action

A. Typhoon Resilience

In 2022, the MSC Zoe lost 342 containers in a North Sea storm. Forensic analysis revealed that intact corner castings prevented catastrophic structural failure in 90% of surviving units, allowing salvage teams to recover cargo.

B. Cold Chain Assurance

Reefer containers transporting vaccines rely on corner castings to maintain airtight seals. Damaged castings can compromise insulation, risking temperature fluctuations—a critical factor in Pfizer’s COVID-19 vaccine shipments.

C. Heavy Machinery Transport

When Siemens shipped gas turbines from Germany to Australia, open-top containers with reinforced castings absorbed vibration forces 3x higher than standard loads, preventing $2M in potential damage.

4. Innovations Enhancing Protection

Smart Castings: IoT-enabled sensors embedded in castings monitor real-time stress, corrosion, and twist-lock engagement, transmitting alerts via satellite (e.g., Maersk’s Remote Container Management).

Composite Materials: Carbon-fiber-reinforced castings (tested by COSCO) reduce weight by 30% while maintaining strength.

Robotic Inspections: AI-powered drones in ports like Rotterdam scan castings for micro-cracks missed by human crews.

5. Challenges and Solutions

Metal Fatigue: Repeated stress cycles can weaken castings. Solution: Ultrasonic testing during maintenance.

Counterfeit Parts: Substandard castings caused a 2019 container collapse in Singapore. Response: Blockchain-based certification (adopted by Hapag-Lloyd).

Arctic Shipping: Specialized castings with -60°C ratings (developed by MSC) prevent brittleness in polar routes.

In the unforgiving realm of maritime transport, corner castings are silent sentinels—absorbing shocks, defying corrosion, and anchoring global trade. Their resilience ensures that everything from smartphones to life-saving medicines reaches shores intact. As shipping confronts climate change and automation, advancements in casting technology will remain vital to navigating tomorrow’s oceans.

Hot News

Hot News