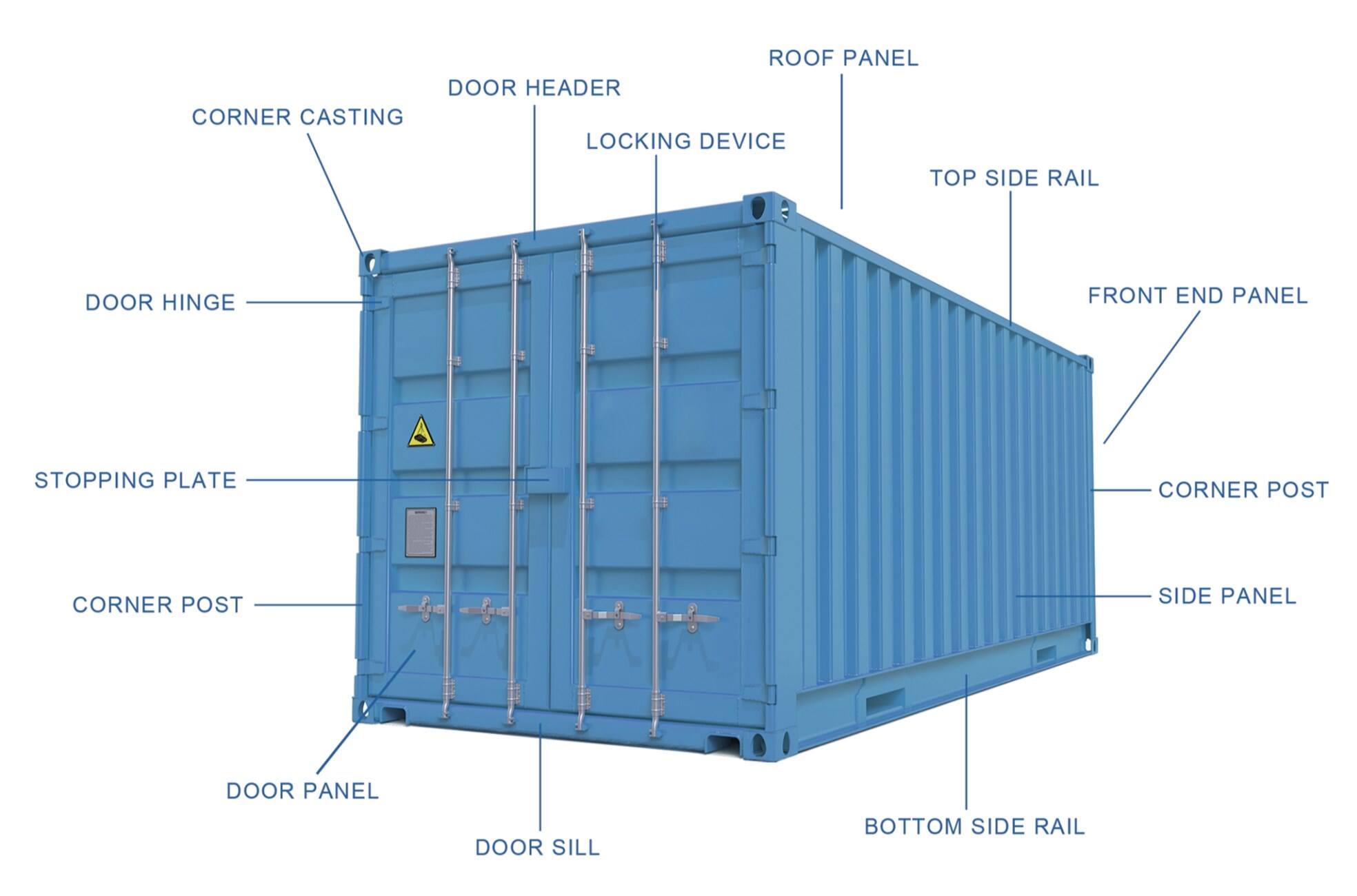

When we think of shipping containers, we often picture their steel walls or standardized dimensions. Yet, one of the most critical components lies at their eight corners: the corner castings. These unassuming metal blocks, typically made of cast steel, are the backbone of containerization, enabling seamless logistics across air, land, and sea. This article explores the multifaceted roles of corner castings and their evolving applications in modern industries.

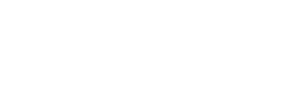

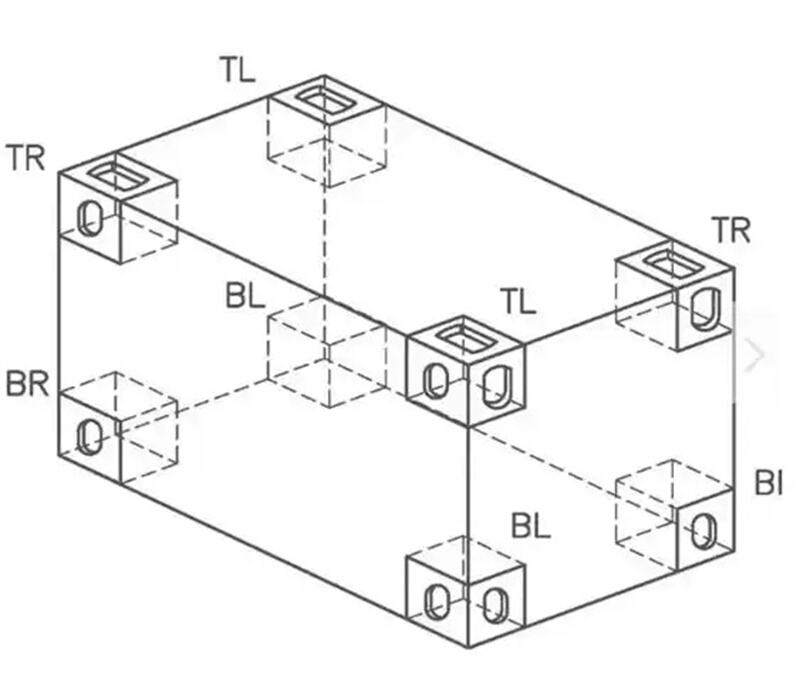

1. The Anatomy of Corner Castings

Corner castings are precision-engineered fittings welded to each corner of a shipping container. Their standardized design (defined by ISO 1161) includes:

Apertures: Rectangular openings for twist-lock mechanisms.

Reinforced edges: Built to withstand vertical stacking loads up to 200 tons.

Corrosion resistance: Often coated with zinc or epoxy for durability in harsh environments.

2. Core Applications in Global Logistics

A. Lifting and Handling

Corner castings are the primary interface for cranes, straddle carriers, and forklifts. Their apertures allow twist locks to securely grip containers during:

Port operations: Efficient loading/unloading from ships.

Rail and truck transport: Safe transfer between intermodal vehicles.

Disaster relief: Rapid deployment of containers in emergencies.

Example: A 40-foot container weighing 4 tons can be lifted in under 2 minutes using corner casting-compatible spreader bars.

B. Stacking and Stability

The castings’ reinforced structure enables vertical stacking of up to 9 containers (depending on design), critical for:

Ship storage: Maximizing cargo capacity in vessel holds.

Container yards: Space-efficient storage in ports.

Modular architecture: Stabilizing multi-story container buildings.

C. Intermodal Locking

Corner castings integrate with:

Twist locks on trucks and railcars to prevent shifting.

Lashing systems for aircraft cargo (e.g., military transport planes).

3. Beyond Transportation: Innovative Use Cases

A. Modular Construction

Architects repurpose corner castings to:

Anchor prefabricated homes.

Connect hybrid structures (e.g., container-glass composites).

Support rooftop solar panels on container-based offices.

B. Military and Aerospace

Rapid-deployment units: Military shelters use castings for helicopter airlifting.

Satellite transport: Customized castings protect sensitive payloads during road-to-launchpad transit.

C. Smart Logistics

IoT-enabled corner castings now feature:

RFID tags: Tracking container movements in real time.

Load sensors: Monitoring weight distribution to prevent overstacking.

Corrosion detectors: Alerting maintenance teams via satellite.

4. Challenges and Innovations

Fatigue failure: Repeated stress at corners can lead to cracks. Solutions include laser-scanned quality control and graphene-enhanced steel.

Climate adaptation: Arctic-grade castings withstand -50°C, while desert variants resist sand abrasion.

3D-printed prototypes: Companies like Maersk test lightweight aluminum castings for specialized containers.

Conclusion

Corner castings are far more than mundane metal blocks—they are the linchpin of global trade, ensuring safe, efficient, and scalable cargo movement. From enabling megaship economies of scale to anchoring futuristic smart cities, their applications continue to expand. As logistics evolve with automation and sustainability demands, corner castings will remain at the forefront, quietly holding the world’s commerce together.

Hot News

Hot News