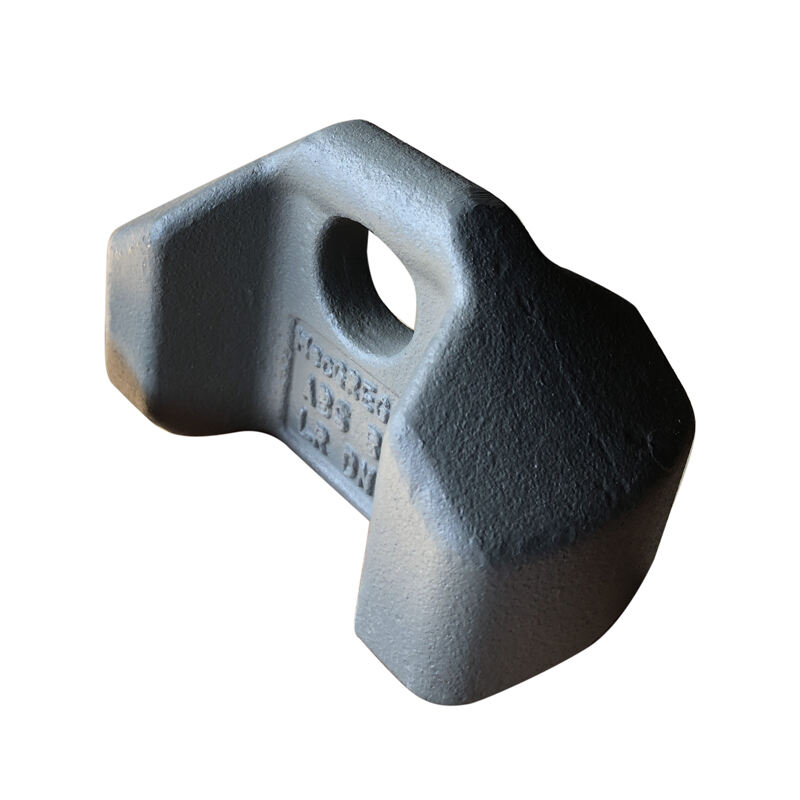

ISO container corner casting is a key component to the structural integrity of ISO shipping containers. It secures the corners of the container and makes it possible to stack the containers safely. In this article, we’ll be discussing the various types of corner castings in ISO containers, why good top-quality castings are necessary, and how to inspect and maintain them for safety and durability

One piece of an ISO Container that is critical to keep in mind is the container casters from Esen. They're the metal fittings at all four corners of a container that secure the container for lifting and stacking. These castings are very important to the strength of the container and to the integrity of the contents being carried.