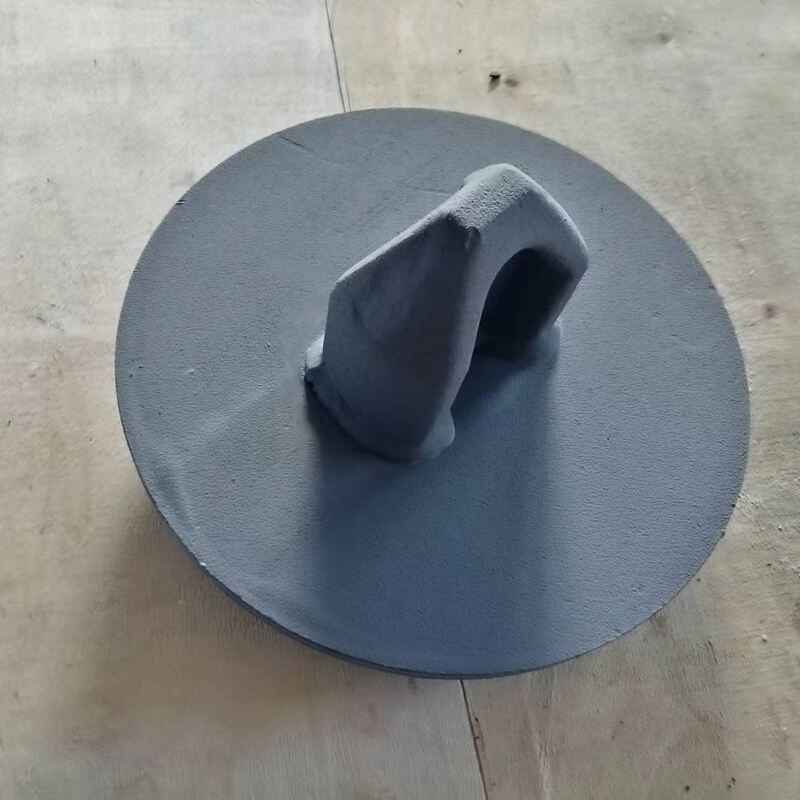

If they are, then corner castings are the shipping container equivalent of superheroes. They don’t have capes or superpowers, but the job they do is vital to making sure containers stay strong and secure during transport. Why don't you join me we'll go under the hood and check out how these little guys protect and make our stuff get from A to B?

If not for the corner castings, you would not be able to stack containers on top of each other. This in turn would restrict the amount of goods that can be transported at the same time by ships, trucks and trains, resulting in more expensive shipping and longer delivery times. In more laymen terms, corner castings are those which allow us the luxury of having products available to us in abundance at any given time.